Since 1977, Mecmesin has been developing reliable power, product quality and torque testing solutions for quality control, so that our customers around the world can get stable and accurate test results every time.

Operating in accordance with strict ISO 9001 quality standards, Mecmesin products are used to ensure the quality of components, materials and finished products for a wide range of testing applications in all industries.

Operating in accordance with strict ISO 9001 quality standards, Mecmesin products are used to ensure the quality of components, materials and finished products for a wide range of testing applications in all industries.

Mecmesin Testing machines

Fill out the form

We will contact you as soon as possible

Model range:

The MultiTest-dV line of testing machines integrates perfectly with our VFG touchscreen force meter (as well as its simplified AFG version), making it a popular configuration for stand-alone applications requiring peak load value capture.

Expand its capabilities by connecting to the VectorPro Lite software for graphical representation of data and performing calculations to view test results.

MultiTest-dV can be configured on two levels:

— Basic

— Advanced

Expand its capabilities by connecting to the VectorPro Lite software for graphical representation of data and performing calculations to view test results.

MultiTest-dV can be configured on two levels:

— Basic

— Advanced

MultiTest-dV

Motorized test bench

Motorized test bench

Features:

The MultiTest-dV is an excellent motorized strength tester offering outstanding value. Designed for precision compression and tensile testing, the MultiTest-dV with simple controls supported by sophisticated electronics makes it an ideal choice for a wide range of routine tests.

This significantly improves the variability encountered with manual testers, where stretching and compression are applied manually at different speeds. By applying force at a constant speed and evenly gripping the sample, the MultiTest-dV motorized test bench significantly increases the reproducibility of test results.

Operators can perform routine periodic tests with excellent throughput, minimizing testing time and taking advantage of the convenience associated with these motorized tensile testers.

This significantly improves the variability encountered with manual testers, where stretching and compression are applied manually at different speeds. By applying force at a constant speed and evenly gripping the sample, the MultiTest-dV motorized test bench significantly increases the reproducibility of test results.

Operators can perform routine periodic tests with excellent throughput, minimizing testing time and taking advantage of the convenience associated with these motorized tensile testers.

Available options:

Basic version:

Up to the test target travel limit, or, when using any line of force sensors Mecmesin — s touch screen (VFG), improved power gauge (AFG) — up load limit or rupture. Add VectorPro™ Lite software to the MultiTest-dV with a sensor for data collection, plotting, calculating results, as well as reporting and exporting test data.

Up to the test target travel limit, or, when using any line of force sensors Mecmesin — s touch screen (VFG), improved power gauge (AFG) — up load limit or rupture. Add VectorPro™ Lite software to the MultiTest-dV with a sensor for data collection, plotting, calculating results, as well as reporting and exporting test data.

Extended version:

Install a special ELS load cell and connect to the VectorPro MT software to use the MultiTest-dV as an entry-level testing machine. Control the entire test sequence using simple step-by-step programs. Perform both standard calculations such as peak load, displacement load, and more complex calculations such as Young's modulus and yield stress displacement.

Install a special ELS load cell and connect to the VectorPro MT software to use the MultiTest-dV as an entry-level testing machine. Control the entire test sequence using simple step-by-step programs. Perform both standard calculations such as peak load, displacement load, and more complex calculations such as Young's modulus and yield stress displacement.

The design of the test machine:

MultiTest-dv is a versatile single—column motorized test bench designed for ease of use by operators of all levels. In line there are 3 models nominal force of 0.5 kN, 1 kN and 2,5 kN with the crosshead speed until 1200 mm (47 inches). Each of them takes up a minimum of space on the table and is ideal for applying tensile and compressive forces in various applications.

This versatile testing machine provides excellent performance thanks to the control panel and the multifunctional control wheel, which allows you to accurately select test parameters such as speed and integral force/displacement. Colored LEDs clearly show the condition of the machine during testing, and operators can easily monitor the progress of the test from the force and displacement panel. For deeper recording and analysis of test data, the MultiTest-dV can be connected via a USB output port to the advanced VectorPro Lite software package for data collection and plotting. Adjustable safety limit switches ensure excessive stretching of the samples or crushing of the grips.

The MultiTest-dV is equipped with a dovetail traverse for quick and easy replacement of force sensors or load cells. The grippers and fixtures can be quickly installed on the base, on which threaded holes are pre-drilled for easy installation of various accessories. Neither one model doesn’t weighs over 31 kg (68 lb), and them compact design and small footprint make these test stands are the ideal desktop device for use in laboratory quality control or production area.

Force sensors

Our digital force sensors are self-contained devices consisting of an internal load cell and its own display. We recommend our VFG dynamometers with touchscreen or AFG (Advanced Force Gauges) for use with the MultiTest-dV series universal testing machine. There are 10 models force measuring sensors effort from 2.5 to 2500 N (0,5 500 lbf) each which has an impressive accuracy of ±0.1% full scale.

The dynamometer is positioned on the traverse of the test frame using a dovetail mount and continuously measures and displays tension/compression, while simultaneously recording maximum peak readings in the background. When the dynamometer is connected to stand MultiTest-dV via interface cable, he can transmit the displayed readings load real time front panel and perform basic management challenge. This is achieved by adjusting the parameters on the dynamometer to send a signal to the test bench to "stop" or "stop and reverse" when a load limit or sample failure is detected. The values of tension and compression obtained using a dynamometer can be transmitted directly toA PC or printer to record the results.

In as an alternative to the testimony of the efforts are combined readings move MultiTest-dV and go on USB output port to generate a data packet access which is software VectorPro Lite to build charts, calculate the results and creation of test reports.

Improved load cells

Advanced load sensing (ELS) is on traverse test frame interacts with MultiTest-dV for precise control of materials combination software VectorPro MT. There are 13 models effort from 2.5 to 2500 N (0,5 500 pounds-force), and all of them are completely interchangeable, and them calibration immediately recognized MultiTest-dV. This ensures that you will have the optimal choice to meet all your material testing needs without the need for lengthy setup. The measurement accuracy is ±0.5% of the readings.

Devices and grips for testing

Holding the test sample in place without slipping is essential to obtain reproducible results. Mecmesin offers a wide range of grippers and attachments for fastening various components and materials. They include wedge-shaped grippers and vises for tensile testing, compression plates and bending devices, friction tables and much more.

This versatile testing machine provides excellent performance thanks to the control panel and the multifunctional control wheel, which allows you to accurately select test parameters such as speed and integral force/displacement. Colored LEDs clearly show the condition of the machine during testing, and operators can easily monitor the progress of the test from the force and displacement panel. For deeper recording and analysis of test data, the MultiTest-dV can be connected via a USB output port to the advanced VectorPro Lite software package for data collection and plotting. Adjustable safety limit switches ensure excessive stretching of the samples or crushing of the grips.

The MultiTest-dV is equipped with a dovetail traverse for quick and easy replacement of force sensors or load cells. The grippers and fixtures can be quickly installed on the base, on which threaded holes are pre-drilled for easy installation of various accessories. Neither one model doesn’t weighs over 31 kg (68 lb), and them compact design and small footprint make these test stands are the ideal desktop device for use in laboratory quality control or production area.

Force sensors

Our digital force sensors are self-contained devices consisting of an internal load cell and its own display. We recommend our VFG dynamometers with touchscreen or AFG (Advanced Force Gauges) for use with the MultiTest-dV series universal testing machine. There are 10 models force measuring sensors effort from 2.5 to 2500 N (0,5 500 lbf) each which has an impressive accuracy of ±0.1% full scale.

The dynamometer is positioned on the traverse of the test frame using a dovetail mount and continuously measures and displays tension/compression, while simultaneously recording maximum peak readings in the background. When the dynamometer is connected to stand MultiTest-dV via interface cable, he can transmit the displayed readings load real time front panel and perform basic management challenge. This is achieved by adjusting the parameters on the dynamometer to send a signal to the test bench to "stop" or "stop and reverse" when a load limit or sample failure is detected. The values of tension and compression obtained using a dynamometer can be transmitted directly toA PC or printer to record the results.

In as an alternative to the testimony of the efforts are combined readings move MultiTest-dV and go on USB output port to generate a data packet access which is software VectorPro Lite to build charts, calculate the results and creation of test reports.

Improved load cells

Advanced load sensing (ELS) is on traverse test frame interacts with MultiTest-dV for precise control of materials combination software VectorPro MT. There are 13 models effort from 2.5 to 2500 N (0,5 500 pounds-force), and all of them are completely interchangeable, and them calibration immediately recognized MultiTest-dV. This ensures that you will have the optimal choice to meet all your material testing needs without the need for lengthy setup. The measurement accuracy is ±0.5% of the readings.

Devices and grips for testing

Holding the test sample in place without slipping is essential to obtain reproducible results. Mecmesin offers a wide range of grippers and attachments for fastening various components and materials. They include wedge-shaped grippers and vises for tensile testing, compression plates and bending devices, friction tables and much more.

Technical specifications:

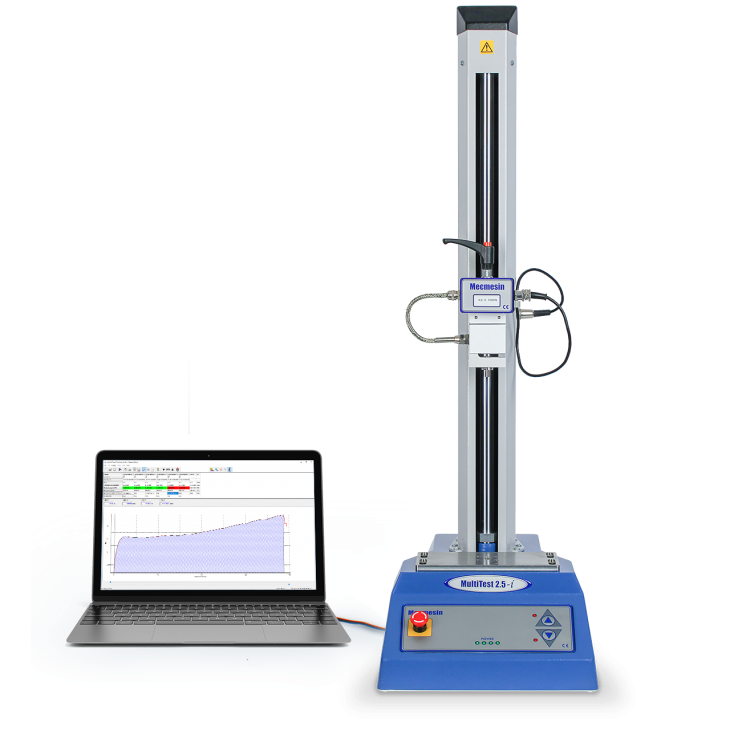

The MultiTest-i Tension and compression tester (universal testing machine) is controlled by software installed on a personal computer.

This UIM ensures the stability and reliability of the tests by controlling key test parameters such as force, displacement and speed. This means that the inherent variability found when using manual test methods is almost completely eliminated. Quality control specialists around the world rely on universal testing machines to objectively assess the mechanical strength of their components, assemblies and finished products.

This UIM ensures the stability and reliability of the tests by controlling key test parameters such as force, displacement and speed. This means that the inherent variability found when using manual test methods is almost completely eliminated. Quality control specialists around the world rely on universal testing machines to objectively assess the mechanical strength of their components, assemblies and finished products.

Multitest-i

Single-column testing machine

with control from a personal computer

Single-column testing machine

with control from a personal computer

Features:

Single column testing machine series MultiTest-i is the ideal solution for measuring forces up to 5 kN on different components made from virtually any material in the time of their normal operation and tensile/compression until the samples fail or break. Their compact design ensures that they occupy very little space on the table, and intuitive controls use the software makes them easy to use even for novice operators.

The versatile design of these single column testing machines means that you can experience samples high elongation models long stroke 0.5 kN and 1 kN, which makes them ideal for testing and plastics rubber stretching and adhesion flaking. In you you can choose from our popular models maximum loads up to 2,5 kN and 5 kN universal testing small samples identify characteristics of tensile, compression, bending, shear and destruction. Whichever tester you choose, you can be sure that Mecmesin will provide you with an affordable solution that will not break your budget. That's why customers from various industries such as automotive, aerospace, cosmetics, electronics, packaging, pharmaceuticals, and medicine rely on Mecmesin in as a preferred partner when it comes to trials stretching and compression

The versatile design of these single column testing machines means that you can experience samples high elongation models long stroke 0.5 kN and 1 kN, which makes them ideal for testing and plastics rubber stretching and adhesion flaking. In you you can choose from our popular models maximum loads up to 2,5 kN and 5 kN universal testing small samples identify characteristics of tensile, compression, bending, shear and destruction. Whichever tester you choose, you can be sure that Mecmesin will provide you with an affordable solution that will not break your budget. That's why customers from various industries such as automotive, aerospace, cosmetics, electronics, packaging, pharmaceuticals, and medicine rely on Mecmesin in as a preferred partner when it comes to trials stretching and compression

The design of the test machine:

Single column testing machine MultiTest-i MultiTest-xt equipped with a motorized test frame ball screw transmission, which is designed for application to tension and compressive forces from multiple mn before 5 kN. Its high-quality construction, manufactured in accordance with ISO 9001 quality standards, ensures maximum test repeatability. In an effort to accurately measure forces over a wide range, it is often necessary to use several load cells. The design of the MultiTest traverse in the shape of a dovetail allows the operator to minimize the changeover time by quickly and easily pointing a new load cell, which is automatically recognized by the software.

The MultiTest-i and MultiTest-xt base plates are pre-drilled and equipped with threaded holes for direct installation of a wide range of grips and fasteners. It also supports quick-change adapters (QC), which speed up the change of grips when you need to perform many different tests. Its versatile design means that the test frame has sufficient distance to accommodate high samples and sufficient travel to measure the tensile strength of the most elastic materials.

Use your own A PC to run the software and take advantage of its small footprint to make it an ideal choice as a desktop tester for tension and compression.

Force sensors

The ILC line of interchangeable load cells is specially adapted to MultiTest-i and MultiTest-xt. They are connected to the frame, and their calibration characteristics are immediately recognized by the tester without any intervention from the operator. Fourteen different sensors measuring from zero cover the range from 2 Nm to 5 kN. This ensures that you will have the optimal choice that meets all your needs in the tensile and compression tests. The measurement accuracy is ±0.1% or ±0.2% depending on the maximum load of the sensor. Each ILC sensor is supplied as standard with its own calibration certificate, monitored in accordance with national standards.

Software

The Emperor software is the basis of the MultiTest-i and MultiTest-xt test systems. It works on any computer Windows and manage the motor testing machine, collecting data frequency of 1000 Hz from load cell and ILC sensor of the crosshead. Step-by-step testing procedures can be quickly and easily created according to the exact requirements of your testing procedures. The most frequently used test procedures can be simply selected by the operator using the "Favorites" button or from the standard drop-down list.

By plotting measurement data in real time on a graph, the operator can accurately determine how the test sample is working. Preset calculations are used to analyze the data to determine whether the sample meets the criteria of "fit/not fit" quality control specifications. At the end of the test, the powerful reporting module in Emperor™ allows the operator to issue a test report in PDF format. Except for that

Grips and fixtures

Holding the test sample in place without slipping is essential to obtain reproducible results. Mecmesin has developed a range of tension and compression grips to hold various components. These include wedge-shaped grips, vises, clamping devices for peeling, bending devices, compression plates and much more…

Due to the differences in the sizes and shapes of the samples, there is often a need for the development and production of a special gripper. Mecmesin's design engineering team can work with you to develop the best grip for your sample and use our 3D printers to produce lightweight and precise fixtures according to your needs.

The MultiTest-i and MultiTest-xt base plates are pre-drilled and equipped with threaded holes for direct installation of a wide range of grips and fasteners. It also supports quick-change adapters (QC), which speed up the change of grips when you need to perform many different tests. Its versatile design means that the test frame has sufficient distance to accommodate high samples and sufficient travel to measure the tensile strength of the most elastic materials.

Use your own A PC to run the software and take advantage of its small footprint to make it an ideal choice as a desktop tester for tension and compression.

Force sensors

The ILC line of interchangeable load cells is specially adapted to MultiTest-i and MultiTest-xt. They are connected to the frame, and their calibration characteristics are immediately recognized by the tester without any intervention from the operator. Fourteen different sensors measuring from zero cover the range from 2 Nm to 5 kN. This ensures that you will have the optimal choice that meets all your needs in the tensile and compression tests. The measurement accuracy is ±0.1% or ±0.2% depending on the maximum load of the sensor. Each ILC sensor is supplied as standard with its own calibration certificate, monitored in accordance with national standards.

Software

The Emperor software is the basis of the MultiTest-i and MultiTest-xt test systems. It works on any computer Windows and manage the motor testing machine, collecting data frequency of 1000 Hz from load cell and ILC sensor of the crosshead. Step-by-step testing procedures can be quickly and easily created according to the exact requirements of your testing procedures. The most frequently used test procedures can be simply selected by the operator using the "Favorites" button or from the standard drop-down list.

By plotting measurement data in real time on a graph, the operator can accurately determine how the test sample is working. Preset calculations are used to analyze the data to determine whether the sample meets the criteria of "fit/not fit" quality control specifications. At the end of the test, the powerful reporting module in Emperor™ allows the operator to issue a test report in PDF format. Except for that

Grips and fixtures

Holding the test sample in place without slipping is essential to obtain reproducible results. Mecmesin has developed a range of tension and compression grips to hold various components. These include wedge-shaped grips, vises, clamping devices for peeling, bending devices, compression plates and much more…

Due to the differences in the sizes and shapes of the samples, there is often a need for the development and production of a special gripper. Mecmesin's design engineering team can work with you to develop the best grip for your sample and use our 3D printers to produce lightweight and precise fixtures according to your needs.

Technical specifications:

Send

We are open to communication!

Ask a question

for cooperation

or supply of necessary equipment

Ask a question

for cooperation

or supply of necessary equipment

Fill out the form and we will contact you as soon as possible

info@arevlab.com

Supplies of laboratory equipment for all industries

in Armenia and CIS countries

in Armenia and CIS countries

LLC "AREVLAB"

Address: Republic of Armenia,

Yerevan, Artsakh street, 20

TIN 00516716

Address: Republic of Armenia,

Yerevan, Artsakh street, 20

TIN 00516716

©2022- 2024 All rights reserved